“HB0035 High Density Polyethylene” has been added to your cart. View cart

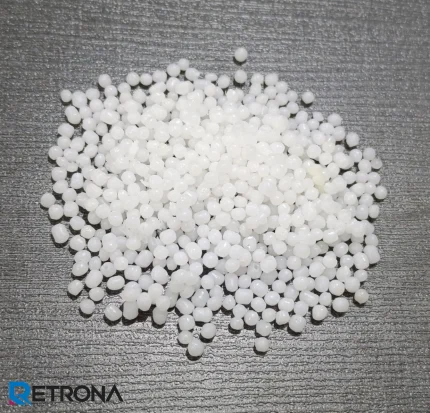

PE100N (CRP100N) High Density Polyethylene

$950.00

- Name: High-Density Polyethylene CRP100N (PE100)

- Group: HDPE Pipe Extrusion

- Density: 0.948 g/cm³, 0.948 g/m³, 0.948 ± 0.002 g/cm³ (typical range 0.948/0.957 g/cm³)

- Melt Flow Rate (MFR):

(190°C/5 Kg): 0.22 g/10min (± 0.03)

(190°C/21.16 or 21.6 Kg): 6.2 g/10min (± 1.0)

SKU:

32012090-PE100N

Categories: Compound Polyethylene, HDPE, Polyethylene, Recycle Polyethylene

Description

CRP100N, also known as PE100N, is a natural high-density polyethylene (HDPE) that uses 1-butene as a comonomer. Designed for high-performance pipe extrusion, PE100N offers excellent long-term hydrostatic strength and outstanding environmental stress crack resistance (ESCR). These properties make CRP100N a dependable choice for demanding pressure pipe systems in industrial and infrastructure applications.

Key Properties:

- High ESCR: Ensures resistance to cracking under long-term mechanical stress and exposure to harsh chemicals and environmental conditions.

- Excellent Impact Resistance: Provides robustness against sudden impacts, reducing the risk of fracture or failure.

- Superior Hydrostatic Strength: Enables pipes to endure sustained internal pressure from liquids or gases over extended periods without rupturing.

- Robust Mechanical Performance: Combines strength, durability, flexibility, and safety with chemical and weather resistance..

Applications

- Pipe Systems:

- Pressure pipes for gas and water distribution, especially at high pressures or where thinner wall designs are needed.

- Industrial piping systems for chemicals and fluids requiring long service life and high resistance to cracking and corrosion.

- Infrastructure and Construction:

- Underground piping for municipal and residential water supply.

- Drainage and sewer systems, benefiting from its corrosion resistance and flexibility under ground movement.

- Industrial and Chemical Applications:

- Storage and transport containers for chemicals and aggressive fluids.

- Equipment components exposed to UV, weathering, or mechanical load.

- Packaging and Outdoor Products:

- Heavy-duty packaging, where impact and weather resistance are essential.

- Outdoor equipment and parts, thanks to its UV stability and resistance to environmental stress.

Data Sheet

Related products

2102TX00 LDPE

2102TX00 is a specific grade of Low-Density Polyethylene (LDPE), known for its excellent flexibility, toughness, and ease of processing. LDPE grades like 2102TX00 are widely used in a variety of applications, including packaging, agricultural films, and industrial uses, due to their ability to perform well in both extrusion and molding processes.

2130 LDPE

2130 LDPE is a grade of Low-Density Polyethylene (LDPE) that is widely used in various applications due to its excellent processing properties, flexibility, and versatility. This material is characterized by its good resistance to low temperatures, chemicals, and impacts, making it suitable for a variety of industrial and packaging applications.

7000F High Density Polyethylene

$970.00

CRP100B (CRP100 BLACK)

$1,000.00

EX3 High Density Polyethylene

$960.00

- Group: HDPE Pipe Extrusion

- Equivalents: SABIC -f00851, GM 5010 T2N, HM 5010 T2N

- Melt Flow Rate (MFR):

-

- 190 °C / 21.6 Kg: 12 g/10min (Amir Kabir notes 12.0 ± 3.0 g/10min)

- 190 °C / 5 Kg: 0.945 or 0.45 g/10min (Amir Kabir notes 0.45 ± 0.05 g/10min)

-

- Density: 0.945 g/cm³ (Amir Kabir notes 0.945 ± 0.002 g/cm³)

EX5 High Density Polyethylene

$950.00